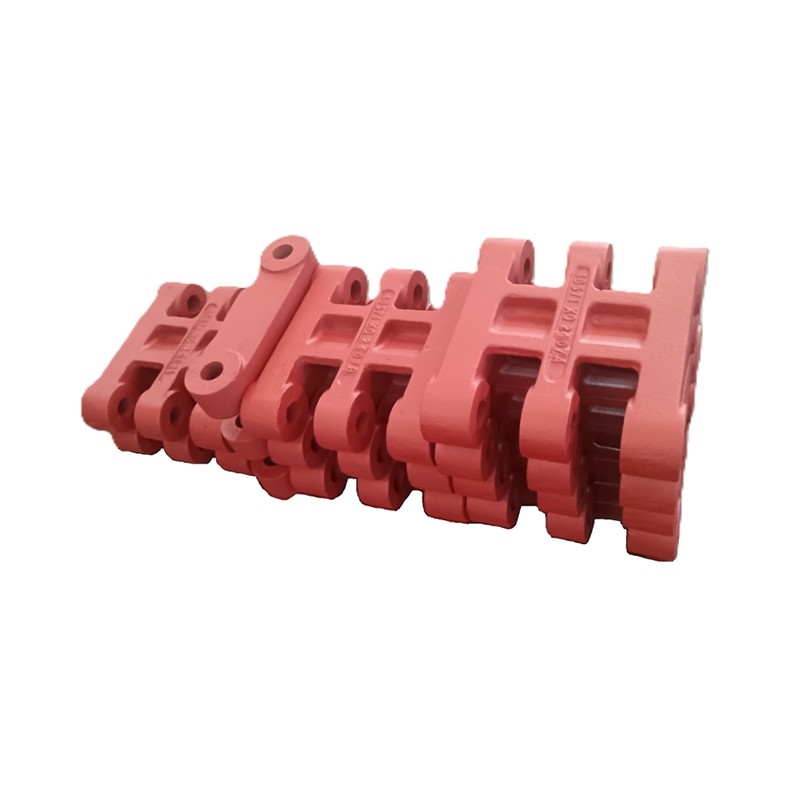

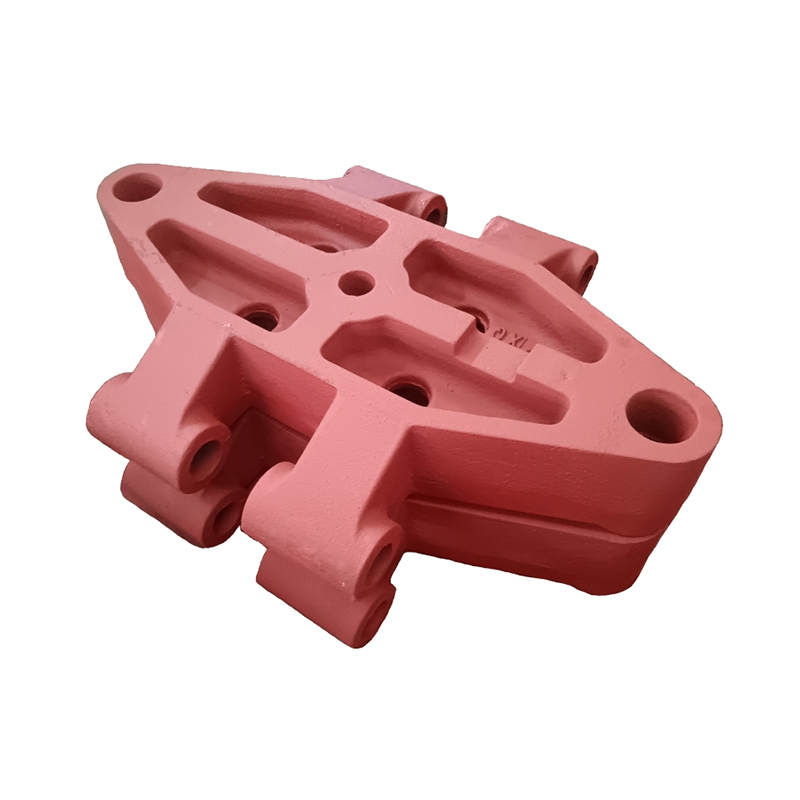

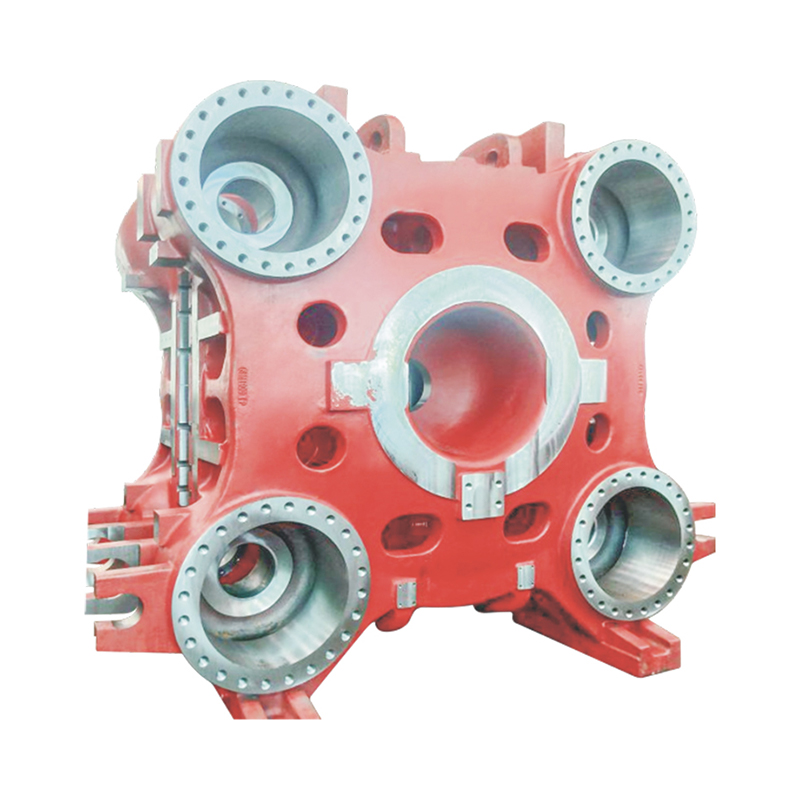

Injection molding machine accessories

Castings for injection molding machines

Castings for injection molding machines refer to metal parts or components used in injection molding machines. These parts are manufactured through a casting process and play an important role in the injection molding process. The castings of injection molding machines mainly provide structural support, strength, and stability for the machine to ensure the smooth progress of the injection molding process. Common injection molding machine castings include base plates, frames, mold supports, guide rails, and clamps. The base plate is the basic supporting component of the injection molding machine, bearing the weight of the entire machine and ensuring stability; the frame casting supports the moving parts of the machine to ensure the coordinated operation of various parts of the machine under high pressure and high temperature conditions; the mold support is used to fix the mold to ensure accurate positioning during the injection molding process; the guide rails and clamps help the precise movement and positioning of the mold to ensure the accuracy of injection molding.

Eng

Eng  中文简体

中文简体